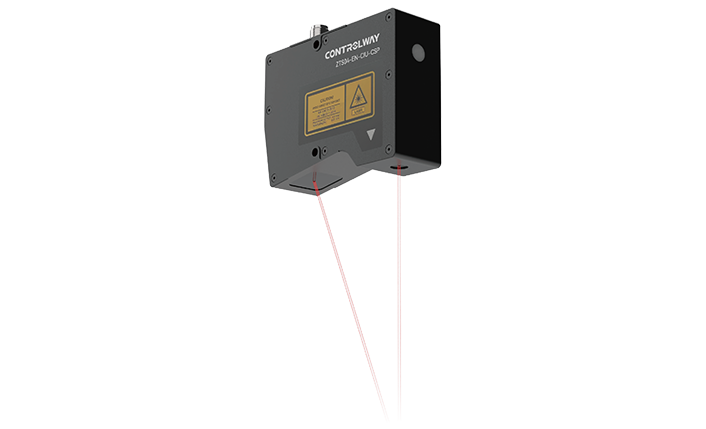

High-precision Laser Triangulation Displacement Sensors

-

Ultra-fast Sampling Rate

-

Ultra-high Linearity

-

Ultra-high Repeatability

-

Simple Interface Configuation

Applications

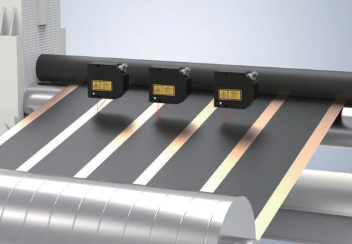

Online Thickness Measurement of Roller Pressed Plates

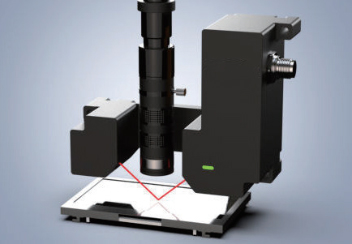

PCB Component Height, PCB Board Thickness measurement

Coaxial height focus measurement

High-frequency vibration measurement

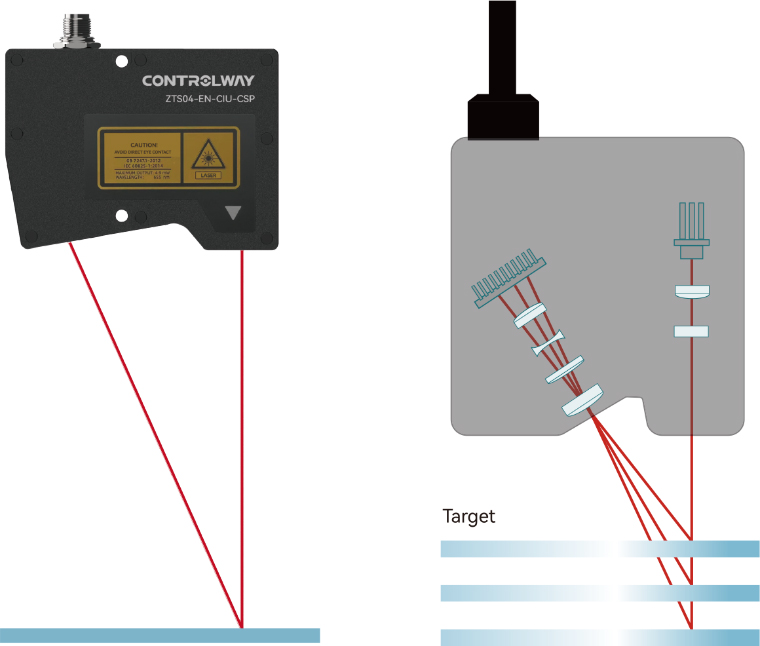

Measurement Principle

The beam of light emitted by the laser shines on the target; the receiving lens focuses the diffusely reflected / reflected light from the surface of the target and focuses it on the photosensitive element. When the distance to the target changes, the position of the light spot on the photosensitive element also changes.

ZTS#-EN-CIU-CSP# Series

| Model | Reference Distance*1 | Measurement Range | Spot Diameter | Repeatability*2 | Repeatability*3 | Linear Error*4 | Outer Diameter*Length | Weight | Sampling Rate | Light Source |

| ZTS0008-EN-CIU-CSP | 8mm | ±0.8 mm | φ20μm | 0.03μm | 0.01μm | < ±0.5μm | 82*115*38.5mm | 213 g | Max. 160 kHz | 655 nm, Max. 4.9 mW |

| ZTS0015-EN-CIU-CSP | 15mm | ±1.0mm | φ35μm | 0.05μm | 0.01μm | < ±0.6μm | 102*137*55.5mm | 475 g | ||

| ZTS0025-EN-CIU-CSP | 25 mm | ±1 mm | φ18μm | 0.05μm | 0.01μm | < ±0.6μm | 120*80*31mm | 372 g | 405 nm, Max. 4.9 mW | |

| ZTS002-EN-CIU-CSPU | 20mm | ±3mm | 30*700μm | 0.05μm | 0.01μm | < ±1.2μm | 76*96*31mm | 303 g | Max. 25kHz | 655 nm, Max. 4.9 mW |

| ZTS003-EN-CIU-CSP | 30mm | ±5mm | φ35μm | 0.15μm | 0.02μm | < ±3μm | 87*76*31mm | 287 g | Max. 160 kHz | |

| ZTS003-EN-CIU-CSPW | 35*400μm | < ±2μm | ||||||||

| ZTS003-EN-CIU-CSPU | 35*1100μm | 0.075μm | Max. 25kHz | |||||||

| ZTS007-EN-CIU-CSP | 70mm | -50~+40mm | φ70μm | 1.3μm | 0.3μm | < ±18μm | 130*90*31mm | 408 g | Max. 160 kHz | |

| ZTS008-EN-CIU-CSP | 80mm | ±15mm | φ70μm | 0.5μm | 0.1μm | < ±6μm | 93*78*37mm | 359 g | Max. 160 kHz | |

| ZTS008-EN-CIU-CSPW | 70*800 μm | |||||||||

| ZTS008-EN-CIU-CSPU | 70*2200 μm | 0.25μm | Max. 25kHz | |||||||

| ZTS015-EN-CIU-CSP | 150mm | ±40mm | φ110μm | 1.2μm | 0.25μm | < ±16μm | 95*80*37 mm | 374 g | Max. 160 kHz | |

| ZTS015-EN-CIU-CSPW | 110*1400 μm | |||||||||

| ZTS04-EN-CIU-CSP | 400mm | ±100mm | φ300μm | 3μm | 1.5μm | < ±60μm | 115*85*37mm | 438 g | ||

| ZTS04-EN-CIU-CSPW | 300*3400 μm | |||||||||

| ZTS045-EN-CIU-CSP | 450mm | ±250mm | φ320μm | 8μm | 2μm | < ±250μm | 120*75*37mm | 416 g | ||

| ZTS045-EN-CIU-CSPW | 320*4200 μm | |||||||||

| ZTS1-EN-CIU-CSP | 1000mm | ±500mm | φ320μm | 12μm | / | < ±500μm | 180*85*40mm | 785 g | ||

| ZTS2-EN-CIU-CSP | 1500mm | ±1000mm | φ400μm | 30μm | / | < ±1000μm | 260*85*45mm | 1250 g | 660 nm, Max. 50mW | |

| ZTS3-EN-CIU-CSP | 2250mm | ±650mm | φ700μm | 50μm | / | < ±650μm | 200*85*41mm | 924 g | ||

| Temperature Characteristics | 0.01% of F.S./°C | |||||||||

| Industrial Interface | Ethernet, RS-485 serial port, analog signal output(Max. ±10V, 4-20mA) | |||||||||

| Measurement & Control Software | Comes with LaserStudio measurement & control software, C++&C# SDK | |||||||||

| Operating Mode | Operates independently without a controller. The head can be configured as a master or slave, the master controls the slave to achieve functions such as synchronous thickness measurement, alternating exposure for interference resistance | |||||||||

| Supply Voltage | DC 9-36V, maximum allowable ±10% fluctuation | |||||||||

| Power Consumption | 2.5W | |||||||||

| IP Grade | IP67 (IEC60529) | |||||||||

| Operating Temperature | 0 to +50°C | |||||||||

*1 Calculation based on the center position of the measurement range;

*2 Measurement of standard white ceramic sample, 50kHz without averaging, taking the root mean square deviation (1 σ) of 65536 sets of measurement data; U series probes, 8kHz without averaging, taking the root mean square deviation (1 σ) of 65536 sets of measurement data;

*3 Measurement of standard white ceramic sample, 50kHz with 1024 averaging times, taking the root mean square deviation (1 σ) of 65536 sets of measurement data; U series probes, 8kHz with 1024 averaging times, taking the root mean square deviation (1 σ) of 65536 sets of measurement data;

*4 Calibration and verification using nanometer-level high-precision laser interferometer.